Amiable Impex, AI Earthing are The Biggest Manufacturer, Exporter and Suppliers of Exothermic Welding Powder and Its Accessories.

Exothermic Welding electrical connections supply from us will never loosen, corrode or increase in resistance. Due to our Superior and Best Quality we are able to sell our product to Railways Contractors, Rail Metro, Telecommunications, Earthing and Lightning Installers Industries as well as to Electrical Suppliers etc.

|

|

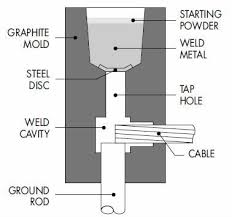

Exothermic welding is also known as Exothermic bonding. There are many advantages of using Exothermic welding. The most important one of Exothermic welding is being that the process produces a molecular joint and not just a mechanical one in between the conductors.Exothermic welding is produced through a starting reactant which provides enough energy to activate the weld reaction. This takes place quickly and safely inside a Graphite mold. The mold is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantee all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel Earth Rod covered with copper, etc. It is especially useful for joining dissimilar metals.

Exothermic welding is a very efficient and cost efficient method of making large or small numbers of high quality electrical connections. Exothermic welding is a simple self-contained system that uses the high temperature reaction of powdered copper oxide and aluminium, within a Graphite Mould, to form permanent electrical connections. The Exothermic welding system requires no external power or heat source, creates high quality electrical connections, is completely portable, can be used safely with minimum training, is cost-effective and can be used for over 45 standard connection configurations. Exothermic welding connections have several advantages in that they are tolerant to repeated faults, are highly conductive, do not loosen and have excellent corrosion resistance because of the very high copper content (>90%) of the alloy.

When Exothermic Welding is used:

Exothermic welding is most commonly used for permanently joining copper conductors. It is the only acceptable means of bonding copper to galvanized cable. It can also be used on stainless steel, cast iron, steel, brass, bronze, and more. If joining two dissimilar metals, exothermic welding is a good option. You'll find Exothermic welding under the names of Such as AIWELD®

Advantages and Disadvantages of Exothermic Welding:

Compared for some other forms of Welding, exothermic bonds employ a greater mechanical toughness. The Welding can be proof against corrosion. You simply won't notice an increase in electrical excess weight despite repeated small signal pulses; your Welding is highly firm. The procedure is more costly, however. The task requires replaceable Graphite Moulds, is not easily repeatable, which enable it to be impeded by means of poor weather conditions if the work is done out of doors.

Exothermic Welding may also be done far from others. That reduces dangers to employees. A igniter is used with widespread graphite molds or a palatable made drop within Welding metal ink cartridge, semi-permanent graphite crucible pattern, and an ignition company that connects your container with a cord.

Exothermic Welding is usually used welding for copper conductors but is suitable for Welding a wide range of metals, including stainless steel, cast iron, common steel, brass, bronze, and Monel. It is especially useful for joining dissimilar metals.

Because of the good electrical conductivity and high stability in the face of short-circuit pulses, Exothermic Weldings are one of the options specified by the grounding conductors and bonding jumpers. It is the preferred method of bonding, and indeed it is the only acceptable means of bonding copper to galvanized cable. The NEC does not require such exothermically Welding connections to be listed or labelled, but some engineering specifications require that completed exothermic Weldings be examined using X-ray equipment.

An Exothermic Welding has higher mechanical strength than other forms of Welding, and excellent corrosion resistance It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to other Welding processes, requires a supply of replaceable mould, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather.

How it Work :

The Exothermic Welding System is a welding process that utilizes an exothermic reaction (a chemical reaction that releases energy in the form of very high temperatures and light) to permanently join metal connections. Exothermic Welding uses a light-weight, clamp-on graphite mold to safely position and contains any welding required. The exothermic reaction creates an intense miniature furnace with temperatures exceeding 2,500 °F, instantly producing molten metal which flows into the weld cavity, filling any available space. After waiting adequate time after the initial process, the mold can be released and the finished connection removed.

Why Use Exothermic Welding:

The Exothermic Connecting created a permanent, homeogreneous, and molecular bond that cannot loosen or corrode, and will carry more current that the conductor.The Exothermic Welding Connection are solid molecular bonds, they do not loosen or corrode over the lifetime of connection. The ame cannot be said about other methods; such as brazing, crimp, split bolt, or compreion type connections.

Overview of Exothermic Welding :

In Exothermic Welding powder, aluminium dust reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly reactive.